Introduction

Choosing the right playground Swivel Chair supplier is a strategic decision, not a routine purchase. It influences safety performance, user experience, compliance approval, and long-term operating costs. Today, buyers look beyond product catalogs and focus on supplier capabilities that determine how rotational playground equipment performs over years of real use. This article examines the capabilities that truly matter, from safety credibility and engineering depth to manufacturing control and lifecycle support, helping decision-makers reduce risk and build durable, future-ready playground environments.

Safety & Compliance Capabilities for Playground Swivel Chair Suppliers

Certified Compliance with Playground Swivel Chair Standards

A capable supplier treats certification as a foundation, not a marketing add-on. For a playground Swivel Chair, compliance with ASTM, CPSC, EN, and IPEMA standards confirms that the equipment aligns with global safety expectations for rotational playground equipment. These standards cover load limits, spacing, fall zones, and rotational behavior. Suppliers with strong compliance systems understand how standards evolve and update designs proactively. They also guide buyers through approval processes, which reduces delays during inspections. This capability signals technical authority and builds trust with municipalities, schools, and commercial developers.

Integrated Safety-by-Design Engineering

Safety works best when engineered into the product from the first sketch. Strong suppliers design playground Swivel Chair systems that manage rotation speed, limit sudden motion, and control access to moving parts. Bearings, shafts, and seat geometry work together to deliver smooth, predictable motion. Fall-zone planning and spacing are also addressed early. This approach improves safety without sacrificing fun. It shows experience in rotational playground equipment design, where motion control matters as much as structure. Buyers benefit from equipment that feels intuitive and reassuring to users.

Documentation, Testing & Audit Readiness

Documentation capability separates reliable suppliers from risky ones. Experienced playground Swivel Chair manufacturers provide test reports, material certifications, and installation manuals without delay. They understand audit workflows for public and commercial playgrounds. Testing data often includes load tests and rotational endurance checks. This readiness reduces project friction and improves approval confidence. It also reflects internal quality discipline. When suppliers support inspections with clear evidence, buyers gain smoother commissioning and fewer compliance questions.

Manufacturing & Material Capabilities That Ensure Playground Swivel Chair Durability

Commercial-Grade Material Selection Expertise

Material choice defines how a playground Swivel Chair performs outdoors. Skilled suppliers select corrosion-resistant metals, UV-stabilized plastics, and sealed bearings that handle moisture, sand, and heavy use. They understand how materials behave under rotational stress. This expertise matters for rotational playground equipment, where friction and wear accumulate over time. A capable supplier explains why specific materials were chosen and how they extend service life. Buyers gain confidence that performance will remain consistent across seasons and climates.

Precision Manufacturing & Quality Control Systems

Precision manufacturing protects motion quality. Reputable playground Swivel Chair suppliers use CNC machining, alignment checks, and rotational balance testing. Quality control occurs at multiple stages, not just final inspection. Each unit must rotate evenly and predictably. Poor alignment increases wear and affects safety. Suppliers with disciplined processes deliver consistent results across batches. This capability reflects operational maturity and protects brand reputation for buyers installing multiple units across sites.

Long-Term Structural Performance Assurance

Durability claims need proof. Strong suppliers validate playground Swivel Chair structures through load testing, fatigue testing, and lifecycle simulations. These tests show how rotational playground equipment behaves under repeated use. Performance assurance reduces uncertainty for buyers planning long-term installations. It also supports warranty confidence. Suppliers who invest in testing demonstrate accountability and engineering depth. They help buyers justify decisions internally using data rather than assumptions.

Design & Engineering Capabilities Focused on User Experience

Age-Appropriate & Inclusive Playground Swivel Chair Design

User experience begins with understanding who plays. Advanced suppliers engineer playground Swivel Chair designs for specific age ranges while supporting inclusive play. Seat height, grip placement, and motion response vary by user group. Inclusive design allows children of different abilities to engage comfortably. This capability reflects awareness of modern playground goals and community expectations. It also improves adoption and satisfaction across user groups.

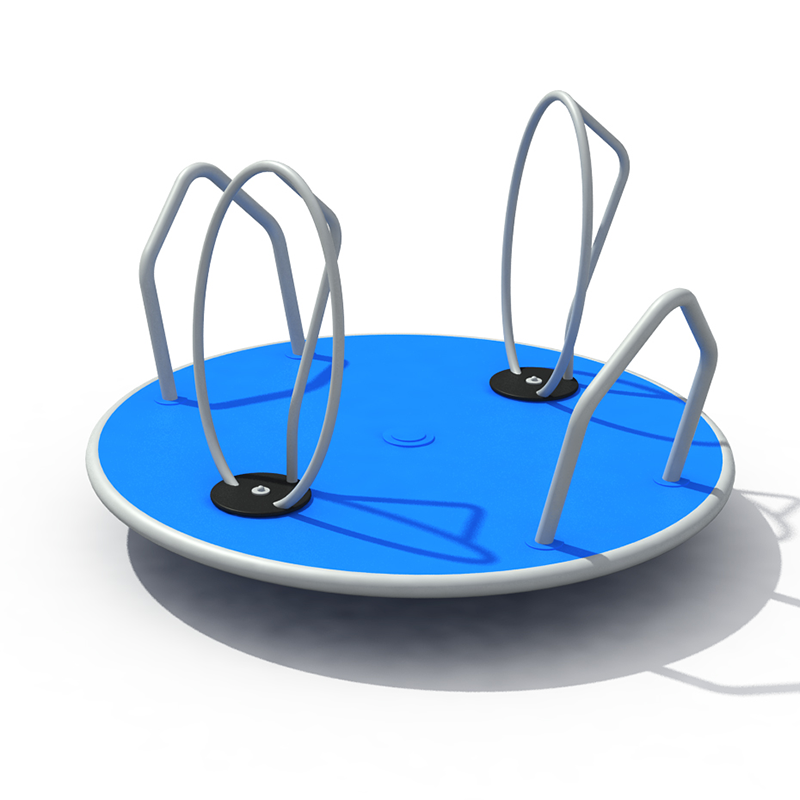

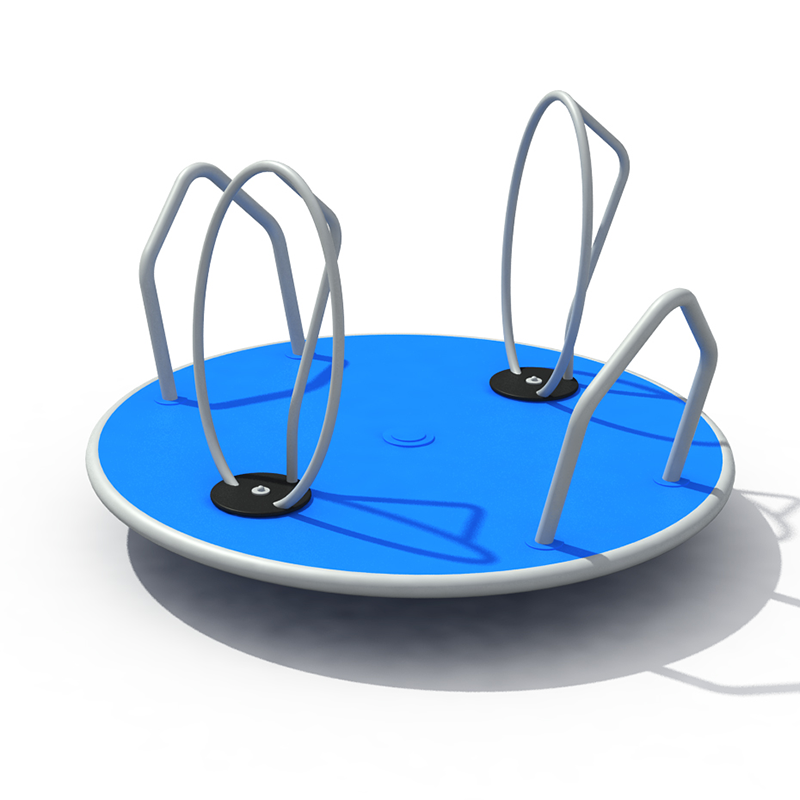

Ergonomic Motion & Sensory Experience Engineering

Motion quality defines enjoyment. Skilled suppliers fine-tune rotation smoothness, resistance, and feedback. For playground Swivel Chair users, controlled motion builds confidence and excitement. Ergonomic seat shapes support posture during rotation. Sensory balance matters in rotational playground equipment, where movement can overwhelm if poorly managed. This engineering capability transforms basic spinning into a repeatable, engaging experience that encourages longer play.

Risk-Controlled Motion Customization

Risk-controlled motion customization relies on measurable mechanical limits rather than subjective adjustments. Advanced playground Swivel Chair suppliers design rotation systems with calibrated damping elements, such as friction sleeves or controlled-bearing resistance, to manage angular velocity under varying loads. This allows rotation speed to remain within safe thresholds even as user mass changes. By defining allowable torque ranges and resistance settings, suppliers ensure rotational playground equipment adapts to site conditions while maintaining consistent safety margins.

Customization & Project Adaptability Capabilities

Site-Specific Playground Swivel Chair Adaptation

Site-specific adaptation requires understanding how ground structure influences rotational stability. Experienced playground Swivel Chair suppliers adjust foundation depth, anchor spacing, and base plate geometry according to soil bearing capacity, concrete strength, or elastic surfacing thickness. Proper adaptation controls settlement and tilt, which directly affect bearing alignment and rotational smoothness. By integrating geotechnical assumptions into mounting design, suppliers ensure consistent performance across diverse site conditions and long-term structural reliability.

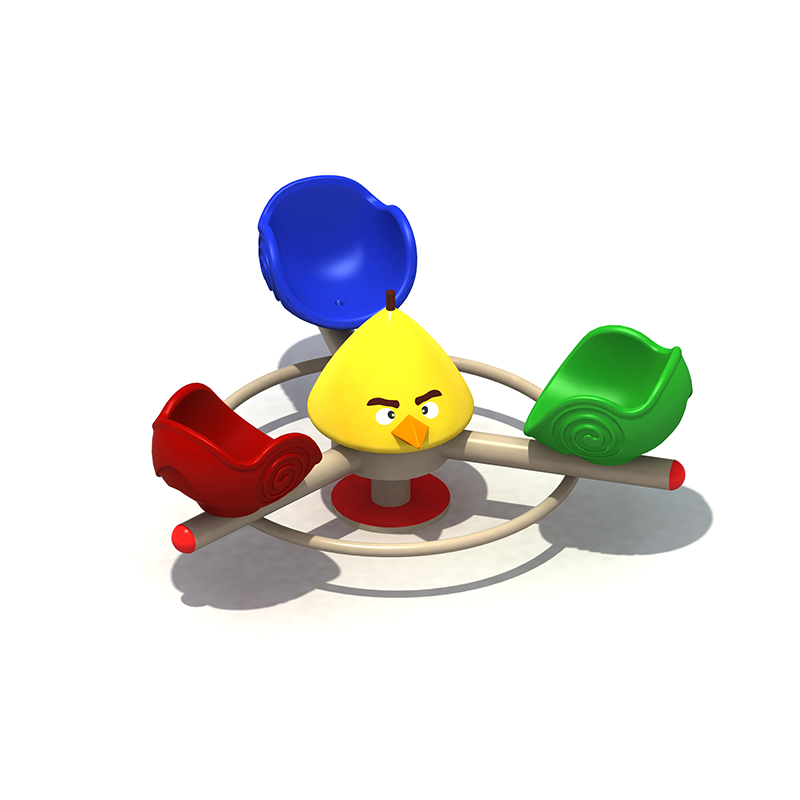

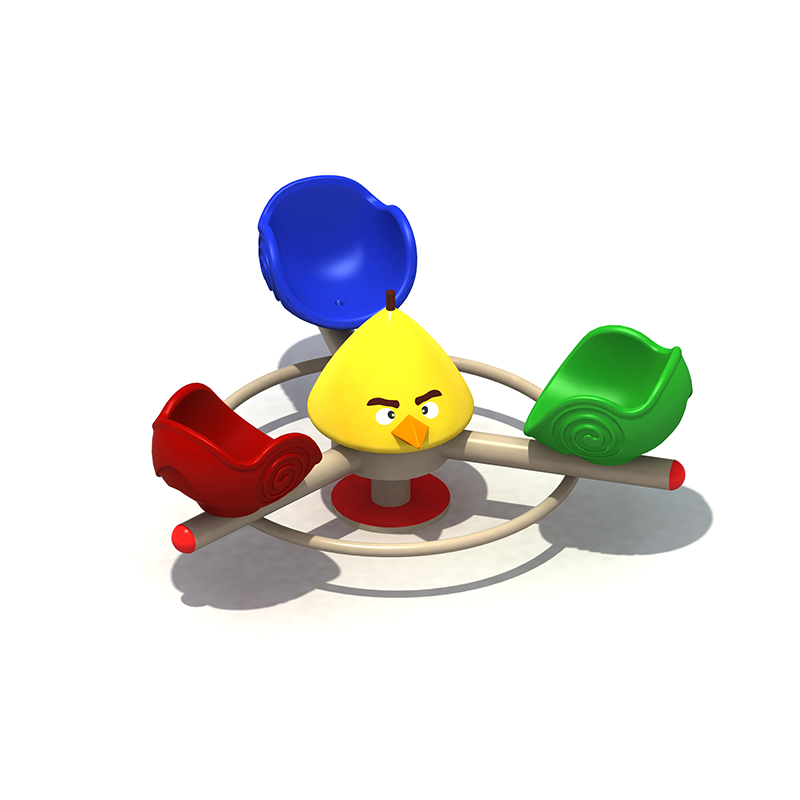

Visual & Thematic Customization Options

Effective visual customization balances aesthetics with material performance. Skilled suppliers apply UV-stable pigments, powder-coated finishes, and non-reflective surfaces that maintain color integrity under prolonged sun exposure. Color contrast is also engineered to support visibility and intuitive use without altering structural components. This coordination between material science and design enables playground Swivel Chair systems to align with thematic goals while preserving durability, safety compliance, and functional consistency.

Scalable Solutions for Different Playground Types

When playground Swivel Chair systems are deployed across schools, public parks, and commercial venues, scalability becomes a technical and operational requirement. Well-designed platforms use standardized modules and interfaces so performance, safety, and maintenance remain consistent even as project size and location vary.

| Playground Type | Typical Application Context | Scalable Design Approach | Key Technical Indicators / Parameters | Operational Considerations |

| Primary Schools | Daily high-frequency use by defined age groups | Standardized base + age-specific seat modules | Recommended user age: 5–12 years;

Max user mass: ≤70 kg;

Rotation speed limit: ≤25 rpm | Prioritize predictable motion and low maintenance |

| Community Parks | Mixed-age, unsupervised public use | Universal platform with adjustable rotation resistance | Max user mass: ≤90 kg;

Bearing load rating: ≥3.0 kN;

Corrosion class: ISO 12944 C3 | Ensure vandal-resistant fasteners and durable coatings |

| Commercial Playgrounds | High traffic, revenue-driven environments | Reinforced modular system with enhanced wear components | Design load: ≥3.0 kN;

Bearing service life: ≥1.5 million cycles | Higher inspection frequency required |

| Multi-Site Installations | Chain parks or municipal networks | Identical core components across locations | Shared bearing type and shaft diameter (≥30 mm);

Common fastener sizes (M10–M12) | Simplifies spare parts inventory and staff training |

| Phased Expansion Projects | Incremental playground development | Pre-engineered expansion-compatible foundations | Anchor spacing tolerance: ±2 mm;

Foundation depth: ≥300–400 mm | Early planning prevents rework during expansion |

| Climate-Variable Regions | Deployment across different environments | Climate-adapted surface treatments on same platform | Operating temperature range: –30 °C to +50 °C;

UV-stabilized polymer components | Material consistency supports predictable aging behavior |

Tip:When managing multiple playground locations, choose playground Swivel Chair platforms that share core mechanical components. Standardized shafts, bearings, and fasteners significantly reduce training effort, spare-part complexity, and long-term maintenance cost.

Installation & Lifecycle Support Capabilities

Professional Installation & Technical Guidance

Professional installation capability reflects how well a supplier translates design intent into real-world performance. Experienced playground Swivel Chair suppliers provide torque specifications for fasteners, foundation depth requirements, and leveling tolerances to ensure stable rotation. They understand how minor misalignment can increase bearing load and friction over time. Training installers on axis alignment, surfacing interface, and post-installation checks helps preserve rotational consistency. This guidance reduces premature wear and ensures the equipment performs as engineered under daily use conditions.

Maintenance Planning & Parts Availability

Effective maintenance planning relies on understanding wear mechanisms in rotational playground equipment. Skilled suppliers define inspection intervals based on bearing load cycles, environmental exposure, and usage frequency. They design playground Swivel Chair systems with modular components, allowing bearings, seats, or fasteners to be replaced without dismantling the entire structure. Clear part identification and long-term availability prevent extended downtime. This structured approach supports predictable maintenance costs and helps operators maintain consistent rotational performance across the equipment’s service life.

Warranty & After-Sales Technical Support

Warranty strength is closely tied to engineering confidence and after-sales competence. Reputable playground Swivel Chair suppliers align warranty terms with tested structural limits and expected wear behavior. Their technical support teams can diagnose issues related to rotation resistance, noise, or alignment using documented performance baselines. Responsive support ensures small deviations are corrected before affecting safety or user experience. This capability demonstrates accountability beyond delivery and supports long-term partnerships built on measurable performance outcomes.

Supplier Experience & Industry Credibility Capabilities

Proven Track Record with Playground Swivel Chair Projects

A proven track record reflects more than project quantity. It shows how a supplier applies engineering judgment across climates, regulatory systems, and usage patterns. Experienced playground Swivel Chair suppliers understand how temperature variation affects bearing viscosity, how coastal environments accelerate corrosion, and how regional safety codes influence layout spacing. Their historical data supports better material selection, rotation control, and anchoring strategies. This applied knowledge lowers uncertainty for buyers expanding into new regions or deploying rotational equipment at scale.

Cross-Disciplinary Expertise

Cross-disciplinary expertise allows suppliers to optimize playground Swivel Chair performance within the full playground system. Engineering teams coordinate with safety specialists and site planners to balance rotation dynamics, fall-zone geometry, and pedestrian flow. This integrated approach improves spatial efficiency and reduces interference between play elements. It also ensures that rotational playground equipment complements surfacing systems, drainage design, and supervision lines. Buyers benefit from solutions shaped by system-level thinking rather than isolated component decisions.

Communication & Partnership Capability

In playground Swivel Chair projects, communication is not a soft skill. It directly influences safety decisions, technical execution, and long-term operational outcomes. Experienced suppliers use structured communication to translate engineering data, application scenarios, and risk boundaries into clear, actionable guidance for buyers.

| Communication Dimension | Practical Application | What the Supplier Should Provide | Key Technical Indicators / Parameters | Buyer & Use Considerations |

| Technical Requirement Alignment | Early-stage specification and selection | Detailed technical datasheets, sectional drawings, material declarations | Design load: ≥2.5–3.0 kN;

Rotation shaft diameter: ≥25–40 mm (steel);

Bearing rated life: ≥1,000,000 cycles | Verify parameters are test-based or standard-referenced |

| Safety Trade-off Explanation | Model comparison and design review | Written explanation of safety vs. experience decisions | Maximum rotational speed: ≤30 rpm (typical for children’s equipment);

Defined rotational damping characteristics (test method stated) | Look for rationale, not just final values |

| Standards & Compliance Communication | Approval and inspection phases | Clause-by-clause mapping to ASTM / EN / CPSC standards | ASTM F1487: entrapment, clearance, accessibility;

EN 1176: dynamic component gaps ≥12 mm | Require clear clause references, not certificate numbers alone |

| Application Scenario Guidance | Varying user density and age groups | Use recommendations and configuration guidance | Recommended users: 1–2 persons;

Maximum single-user mass: ≤70–90 kg | Exceeding design limits increases wear and inspection frequency |

| Lifecycle Communication | Maintenance planning and budgeting | Maintenance schedules and replacement guidance | Bearing service interval: 6–12 months;

Fastener re-torque interval: 3–6 months | Confirm which components are classified as wear parts |

| Risk Boundary Disclosure | Long-term use and environmental exposure | Operating limits and risk advisories | Operating temperature range: –30 °C to +50 °C;

Corrosion category: ISO 12944 C3–C4 | Coastal or high-salinity sites need enhanced corrosion protection |

| Decision-Support Transparency | Multi-option evaluation | Comparative reports and selection rationale | Lifecycle cost comparison (€/year or $/year) | Valuable suppliers explain why some options are not recommended |

Tip:When evaluating a playground Swivel Chair supplier, prioritize those who provide explanatory documentation, not just specifications. Suppliers who clearly explain parameters, standards, and operating boundaries are usually more reliable long-term technical partners.

Conclusion

Choosing the right playground Swivel Chair supplier requires focusing on capabilities rather than product variety. Safety compliance, engineering expertise, durable manufacturing, customization, and lifecycle support determine long-term value. When these factors align, rotational playground equipment delivers safer performance and consistent play experiences over time. Attract Playground Equipment Co., Ltd. adds value through certified designs, precision engineering, and comprehensive services, helping customers achieve reliable, scalable, and future-ready playground Swivel Chair solutions.

FAQ

Q: What capabilities matter most when choosing a playground Swivel Chair supplier?

A: Focus on safety compliance, engineering depth, and lifecycle support for playground Swivel Chair systems used in rotational playground equipment.

Q: Why is safety certification critical for playground Swivel Chair projects?

A: Certified playground Swivel Chair designs ensure rotational playground equipment meets ASTM and CPSC standards, reducing approval risk and safety concerns.

Q: How does manufacturing quality affect playground Swivel Chair performance?

A: Precision manufacturing keeps playground Swivel Chair rotation stable and durable, which improves reliability in rotational playground equipment applications.

Q: Does after-sales service impact long-term value?

A: Yes, strong support keeps playground Swivel Chair systems operating safely and efficiently throughout the lifecycle of rotational playground equipment.