Introduction

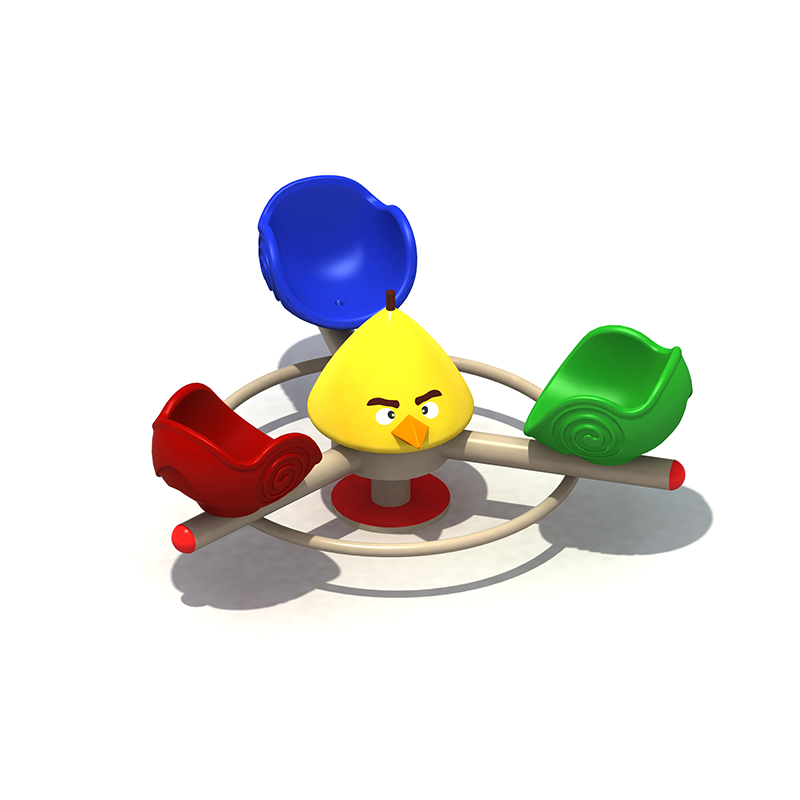

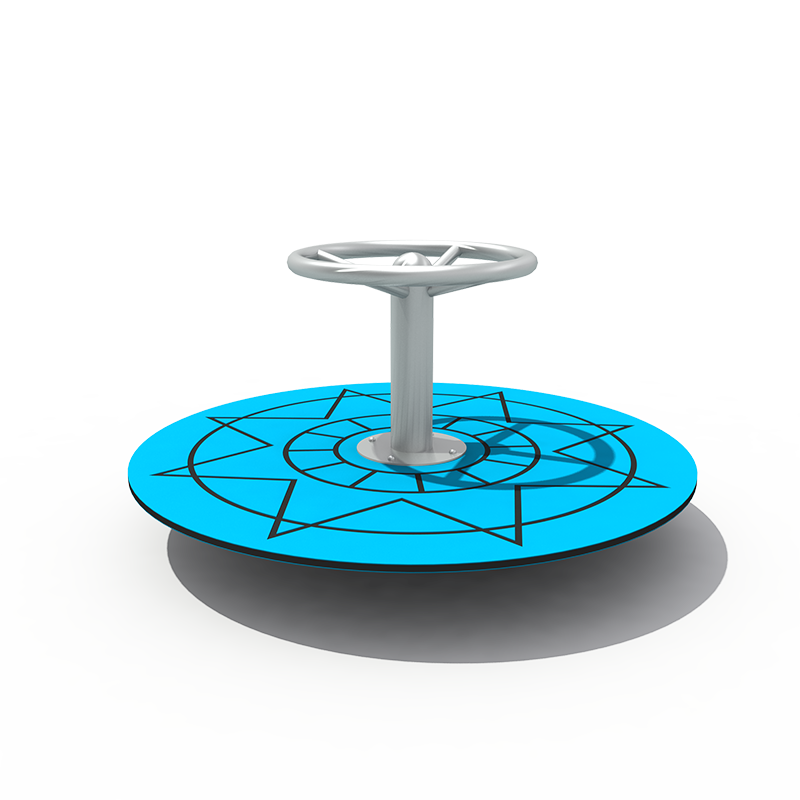

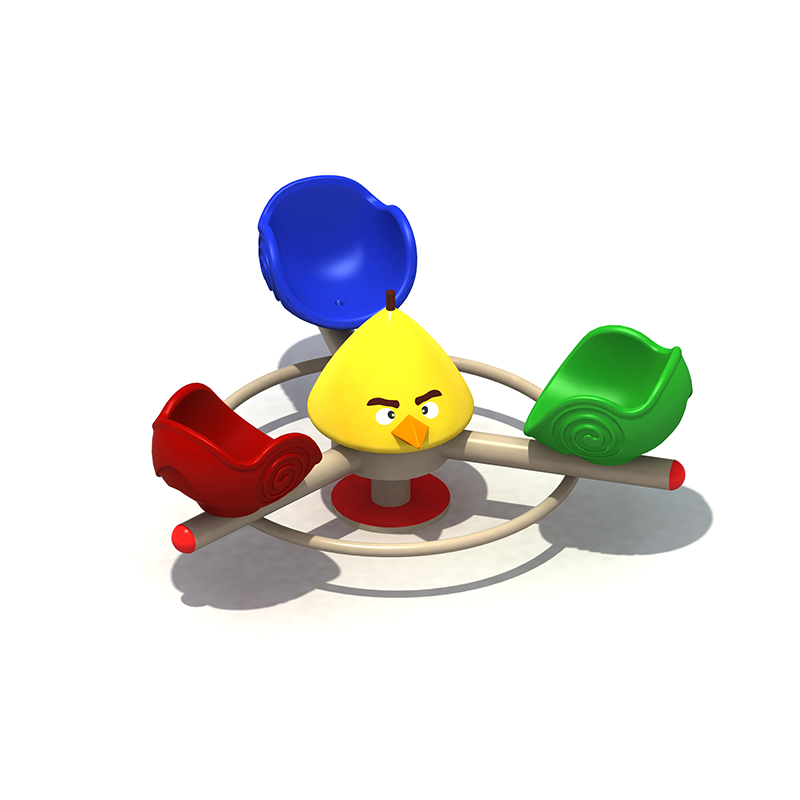

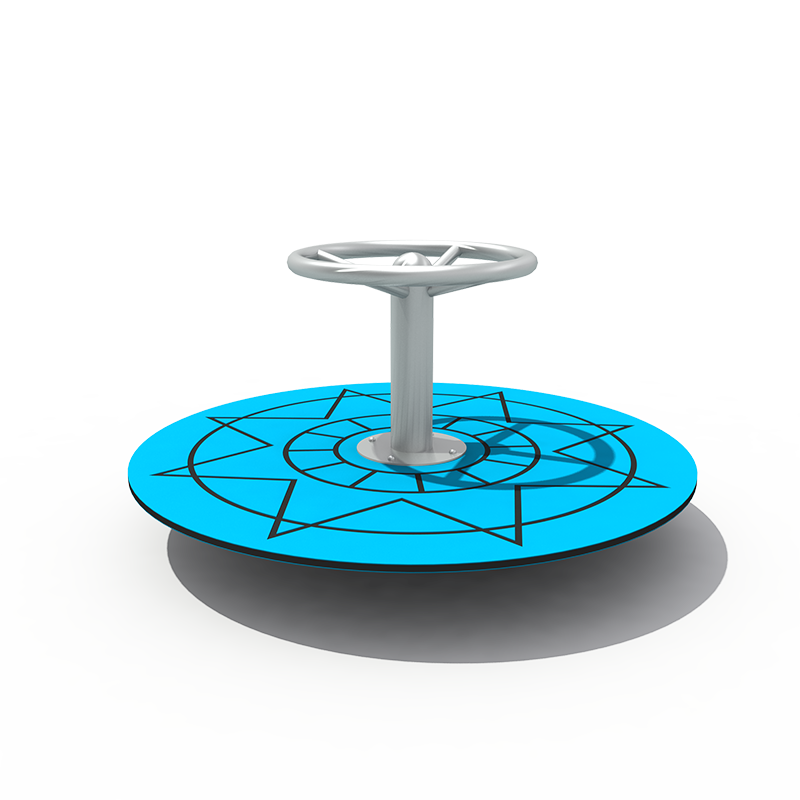

Playground Swivel Chairs are among the most popular and frequently used playground features, driven by children’s natural attraction to spinning motion. Constant rotation places ongoing stress on internal components, even when movement appears smooth. Many operators underestimate this hidden wear. In reality, regular maintenance plays a key role in safety, performance stability, and long-term asset value. This guide explains why routine care matters, what operators should focus on, and how structured maintenance supports reliable, safe playground operations.

Why Regular Maintenance Is Essential for Playground Swivel Chairs

Continuous Rotation and Mechanical Stress

Unlike static play equipment, a playground Swivel Chair operates through constant rotational movement. Each spin places ongoing stress on internal bearings, central shafts, and mounting points. Over time, friction, vibration, and repeated force affect alignment and smoothness. These effects are gradual and often invisible at first. Regular maintenance allows operators to manage this mechanical stress before it influences performance. When rotation stays balanced and controlled, the equipment continues to function as intended and supports consistent play experiences.

Safety Assurance for Daily Public Use

Safety is the primary responsibility of every playground operator. A well-maintained playground Swivel Chair offers predictable movement, stable seating, and controlled spinning speed. When maintenance is consistent, children can use the equipment with confidence. Regular checks help ensure that rotation remains smooth and centered, reducing unexpected movement. This reliability supports safer play patterns and reinforces trust from parents, schools, and communities that rely on the playground every day.

Long-term Value for Playground Operators

Preventive maintenance directly protects the long-term value of a playground Swivel Chair. Routine care reduces the likelihood of sudden downtime and costly replacements. Operators who invest time in inspections and upkeep often extend equipment service life significantly. Over years of use, this approach lowers total ownership cost and supports stable budgeting. Well-maintained equipment also reflects positively on the operator’s management standards and professional reputation.

Core Maintenance Tasks Operators Should Perform Regularly

Visual Inspections of Swivel Chair Structures

Visual inspection allows operators to identify early structural and rotational changes in a playground Swivel Chair without tools or disassembly. By observing movement, alignment, and visible connections, operators can catch subtle deviations before they affect safety or require corrective intervention.

| Inspection Focus Area | What to Observe | Reference Indicators (Industry Practice) | Application in Daily Checks | Attention Points |

| Overall Rotation Path | Whether the chair spins evenly around its vertical axis | Acceptable visible offset: ≤ 3–5 mm at seat edge during rotation | Observe from a fixed point while chair spins freely | Increasing offset suggests developing misalignment |

| Rotation Smoothness | Continuity of motion without jerks or pauses | Smooth rotation with no sudden speed changes | Gently push and release, then watch full spin cycle | Jerky motion often precedes bearing or shaft issues |

| Rotational Resistance | Effort needed to start spinning | Start force typically < 20–30 N hand-applied force (reference range) | Compare feel week to week under similar conditions | Rising resistance indicates internal friction |

| Structural Alignment | Seat, arms, and support column symmetry | All visible components remain perpendicular to ground | View from multiple angles at eye level | Leaning or tilt suggests mounting or foundation shift |

| Fastener Visibility | Bolts, caps, and covers fully seated | No exposed threads beyond design spec | Quick scan around joints and seat base | Exposed threads often mean gradual loosening |

| Surface Contact Points | Unintended rubbing between moving and fixed parts | Clearance maintained as designed, no scuff marks | Look for wear marks or paint abrasion | Contact marks show alignment loss |

| Motion Noise (visual-linked) | Vibration or visible shaking during spin | No visible oscillation at normal speed | Watch seat edges during faster spins | Oscillation often appears before audible noise |

Tip:Perform visual inspections at consistent times, such as before peak usage. Lighting conditions and observation distance should stay similar each time. Consistency helps operators notice small visual changes that might be missed during irregular or rushed checks.

Cleaning High-contact and Rotating Areas

Dirt, sand, and debris often collect around rotating parts and seating surfaces. For a Spinning Seat for Playground, these materials increase friction and interfere with smooth motion. Regular cleaning removes buildup before it affects performance. Clean surfaces also improve hygiene in high-touch areas. This task is simple but highly effective. When done routinely, cleaning supports both mechanical function and user comfort.

Lubrication of Rotating Components

Lubrication plays a critical role in maintaining smooth rotation. Proper lubrication reduces friction, supports even spinning, and protects internal components from premature wear. For a playground Swivel Chair, lubrication should follow a consistent schedule suited to usage levels. Over time, this practice helps maintain stable rotation speed and reduces mechanical strain. Controlled lubrication supports long-term performance without altering the intended play experience.

Maintenance Frequency: How Often Should Playground Swivel Chairs Be Checked?

Daily or Weekly Checks in High-use Areas

Daily or weekly checks are most effective when they follow a consistent observation pattern. Operators should manually rotate the playground Swivel Chair using similar force each time and note differences in start resistance or spin duration. Visual confirmation of seat level and central alignment is equally important. Short, repeatable checks create a baseline for normal performance, allowing operators to detect deviations early and respond before mechanical wear progresses.

Monthly Operational Inspections

Monthly inspections provide an opportunity to assess performance under controlled conditions. Operators can compare rotation smoothness against earlier records and confirm that mounting points remain tight and centered. This inspection cycle supports trend analysis, such as gradual increases in resistance or changes in balance. Regular monthly reviews also help synchronize swivel chair maintenance with other playground equipment servicing, improving overall operational efficiency.

Annual Professional Evaluations

Annual evaluations focus on long-term structural and mechanical integrity. Professionals often assess load distribution, rotational consistency, and foundation stability to confirm the playground Swivel Chair continues to perform within design expectations. These evaluations help operators validate internal maintenance practices and identify adjustments that support future use cycles. Combined with routine checks, annual reviews strengthen reliability and extend service life.

Key Wear Points Operators Should Monitor on Playground Swivel Chairs

Central Swivel and Bearing Assembly

The central swivel and bearing assembly determines how a playground Swivel Chair performs under constant use. It carries vertical loads, manages rotational friction, and keeps movement stable. Because wear often starts internally, operators need a clear, structured way to inspect, measure, and maintain this core system before performance visibly degrades.

| Component / Area | Function in Swivel System | Typical Technical Indicators (Industry-based) | Inspection & Application Focus | Maintenance Notes |

| Central Vertical Shaft | Transfers user load to the base while allowing rotation | Material: carbon steel or stainless steel; Diameter: typically 25–50 mm | Check for vertical alignment and wobble during rotation | Any lateral movement beyond a few millimeters indicates early wear |

| Bearing Type (sealed or semi-sealed) | Reduces friction and ensures smooth spinning | Common types: deep-groove ball bearing; Rated load: 5–15 kN (application-dependent) | Listen for noise and feel resistance during slow manual rotation | Grinding sounds or uneven resistance signal bearing degradation |

| Axial Load Capacity | Supports downward force from users | Typical design load per unit: 100–150 kg static load (varies by model) | Confirm rotation remains smooth under normal user weight | Reduced smoothness under load suggests bearing fatigue |

| Rotational Resistance | Indicates internal friction level | Hand-spin decay time: usually 8–15 seconds for healthy assemblies (reference value) | Compare spin duration over time under similar conditions | Shortening decay time often means rising friction |

| Bearing Lubrication State | Minimizes wear and heat buildup | Grease type: lithium-based or manufacturer-specified; Temp range: −20 °C to +120 °C | Inspect for dryness or contamination near seals | Over-lubrication can attract debris; follow spec |

| Seal Integrity | Protects bearing from sand and moisture | Rubber or polymer seals; IP rating varies by design | Check for cracked or displaced seals | Damaged seals accelerate internal wear rapidly |

| Mounting Interface Tolerance | Keeps rotation centered | Acceptable axial play: typically <1–2 mm (design reference) | Observe off-center spinning during use | Misalignment often starts here, not at the seat |

Tip:When tracking swivel performance, use consistent conditions. Test rotation without riders and with a similar load each time. Comparing spin smoothness and decay trends over months is far more reliable than one-time checks, and it helps operators plan maintenance before user experience changes.

Mounting Hardware and Anchoring Systems

Secure mounting ensures that rotation remains controlled and centered. Anchoring systems connect the playground Swivel Chair to the ground and distribute load evenly. Over time, repeated motion can affect these connections. Regular checks confirm stability and alignment. When anchoring remains solid, the equipment maintains predictable movement and structural integrity.

Surrounding Ground and Surface Conditions

Ground conditions influence both safety and performance. Uneven or shifting surfaces can affect balance and rotation feel. Operators should monitor the area around the Spinning Seat for Playground to ensure it remains level and supportive. Integrating surface care into equipment maintenance improves overall play quality and reduces environmental impact on performance.

Maintenance Records and Operational Best Practices

Why Documentation Matters for Swivel Chair Maintenance

Documentation transforms routine maintenance into measurable operational data. When records include dates, observed rotation behavior, cleaning actions, and lubrication intervals, operators can track performance trends over time. This historical data helps identify recurring patterns, such as gradual increases in rotational resistance or seasonal effects on wear. Documentation also supports internal audits and improves communication between maintenance teams, ensuring that each playground Swivel Chair receives consistent care regardless of staff rotation.

Creating a Simple Playground Swivel Chair Checklist

An effective checklist reflects how the equipment actually functions in daily use. Beyond basic inspection steps, it should include rotation smoothness checks, visible alignment confirmation, and surface condition review. Time-stamped checklists allow operators to correlate maintenance actions with observed performance changes. When applied consistently, a checklist reduces reliance on individual judgment and ensures every playground Swivel Chair is maintained to the same operational standard across sites.

Training Staff for Consistent Maintenance Execution

Structured training links theory with real-world observation. Staff should learn how normal rotation feels and how early deviation appears. Practical training sessions improve sensory awareness, such as detecting resistance changes by hand or spotting minor alignment shifts visually. Consistent training also standardizes terminology and reporting methods. For multi-site operators, trained teams create uniform maintenance quality and reduce variability in playground Swivel Chair care.

Integrating Playground Swivel Chair Maintenance into Overall Playground Management

Coordinating Swivel Chair Care with Playground-wide Inspections

Integrating playground Swivel Chair checks into routine playground inspections improves efficiency and data quality. Operators can align swivel chair observations with scheduled surface, structure, and hardware checks. This reduces duplicated effort and creates a unified inspection record. Coordinated routines also allow inspectors to compare rotational equipment performance against other moving elements on site. Over time, this holistic view supports better maintenance planning, clearer accountability, and more consistent safety standards across the entire playground.

Seasonal Maintenance Planning for Playground Swivel Chairs

Seasonal changes influence how a playground Swivel Chair performs. Higher temperatures can reduce lubricant viscosity, while cold conditions increase rotational resistance. Moisture from rain or snow accelerates contamination around moving parts. Seasonal planning allows operators to adjust inspection frequency, cleaning intensity, and lubrication timing. By anticipating these environmental effects, operators maintain stable rotation behavior and avoid performance fluctuations that often appear during seasonal transitions.

Developing a Proactive Maintenance Mindset

A proactive approach treats maintenance as a continuous process rather than a response to visible issues. Operators who monitor trends in rotation feel, alignment, and wear can schedule adjustments before performance declines. This mindset supports predictable operations and reduces service interruptions. Consistent preventive care also strengthens trust with schools, municipalities, and parents. Over time, proactive management becomes a defining indicator of high-quality playground Swivel Chair operations.

Conclusion

Playground Swivel Chairs require regular maintenance due to constant rotation and high daily use. Consistent inspections, cleaning, lubrication, and documentation help operators control wear, maintain safety, and ensure stable performance. A structured maintenance approach also extends service life and improves long-term value. Attract Playground Equipment Co., Ltd. supports operators with well-engineered swivel chair products and practical service expertise, helping playgrounds achieve reliable operation, safer play experiences, and sustainable asset management.

FAQ

Q: Do Playground Swivel Chairs need regular maintenance?

A: Yes. Playground Swivel Chairs and any Spinning Seat for Playground need routine checks to manage wear.

Q: Why is maintenance important for Playground Swivel Chairs?

A: Playground Swivel Chairs rotate constantly, so maintenance preserves safety, balance, and smooth motion.

Q: How often should a Spinning Seat for Playground be inspected?

A: Playground Swivel Chairs benefit from weekly checks, monthly inspections, and annual professional reviews.

Q: What are common issues during operation?

A: Playground Swivel Chairs may show resistance, noise, or misalignment in a Spinning Seat for Playground.

Q: Does regular care increase service life?

A: Yes. Playground Swivel Chairs last longer when cleaning, lubrication, and inspections are consistent.